The Best Strategy To Use For Best Dust Extractors

Wiki Article

Not known Details About Best Dust Extractors

Table of ContentsThe Ultimate Guide To Best Dust ExtractorsRumored Buzz on Best Dust ExtractorsExcitement About Best Dust ExtractorsBest Dust Extractors - QuestionsBest Dust Extractors for BeginnersThe Ultimate Guide To Best Dust Extractors

Dust control systems for mining procedures have to endure hefty usage but be versatile adequate to adapt to a wide range of conditions. The nature of mining dirt calls for really durable as well as trustworthy devices because mining dirt can be rough and also unpleasant as well as exceptionally fine. The various kinds of mining identify the kind of dust collection system.

The dirt particles from fiberglass have a tendency to stick together regardless of if the procedure is grinding, reducing, or some other type of shaping. To fulfill the standards of OSHA and also NFPA, fiberglass dust collection systems have to have fire and explosion security components. The air high quality for fiberglass dust control systems is carefully kept an eye on due to the wellness threats.

Dust collection systems for this kind of procedure must be especially made to fit the type of finishing being used. The purpose of the system is to manage as well as decrease overspray and dust.

Though presumably most likely to increase airflow and movement, this type of remedy might mishandle and also waste power. The layout of the cubicle depends on the force of the air entering the cell or booth. For many systems, it is essential to have a minor vacuum in the booth to avoid feasible favorable stress (Best Dust Extractors).

See This Report about Best Dust Extractors

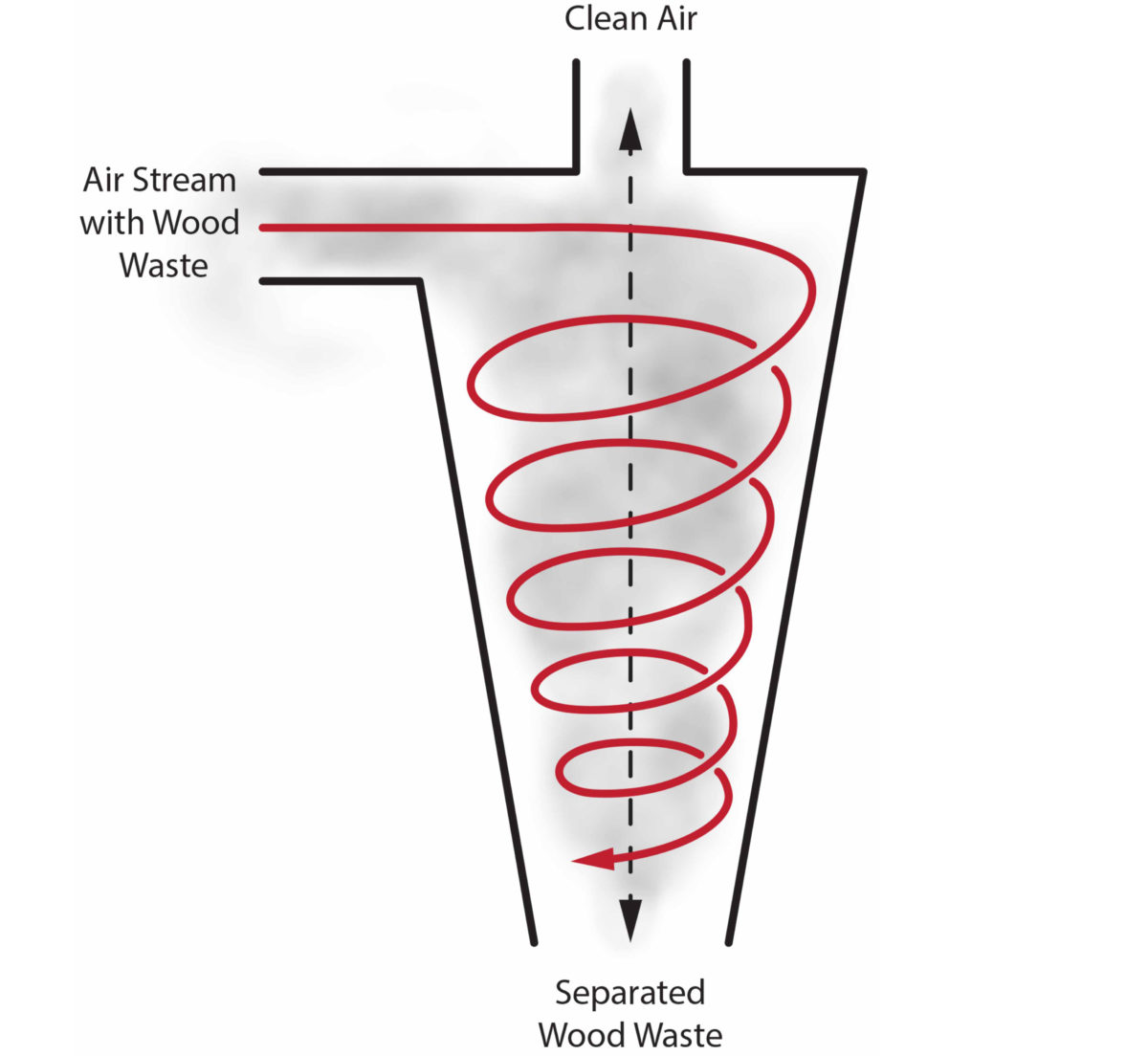

One more technique is simply placing the make-up air connection on the top of the cubicle. No matter the design, it is very important for the cleansing of the air to have cross ventilation. Just like a cleanroom, airflow in a thermal spray cubicle can be either straight or downward, though the downward style is best for dirt collection systems.When makers choose a dust control system, they are encouraged by manufacturers concerning the kind of system that would best fit their requirements because acquiring and also installing a dirt control system is a major investment. Particle matter can be found in a wide array of kinds, from silicon dust to wood chips and also sawdust.

Carbon Penalty carbon dust can be found in different manufacturing processes and also is eliminated utilizing polyester filters. Best Dust Extractors. Molybdenum Molybdenum dirt is created during the mining procedure and is gotten rid of using a baghouse system. Flavor Dust Seasoning dust is created by the production of any type of kind of spice, from cinnamon to sesame seeds.

Sawdust This is the most common product eliminated by dust collection systems. Cartridge or baghouse approaches can be used, with baghouse being the most effective.

What Does Best Dust Extractors Do?

Fabric filter bags in a cartridge system are one of the most effective approach for collecting dust. Concrete Cement dirt is created throughout the motion and transport of the product. Dust collection systems are covered to contain the dirt and also tidy the air. Clay Clay dirt is produced in the production of bricks.

Plastic Dirt More hints High-Density Polyethylene (HDPE) dust is produced in the production of plastic panels when they are shaped and based on a side trimmer, grinder, or miter saw. Paper Dust Among the a lot more usual forms of dust is paper dust, the side impact of the production of different sorts of paper.

With the introduction of dust collection systems, employees are safer and also much more secured. Pulse jet systems are made use of to keep the filters of the dust collection system particulate-free.

A baghouse system is the preferred system. Rice Dirt Rice dirt has very fine and also minute bits that collect during the production of rice-based products. A dirt collection system is required for the security and security of workers. Silica Silica is just one of the most usual compounds on planet. It is a central component of several production operations, such as the manufacturing of glass, ceramic tile, cement, and asphalt.

What Does Best Dust Extractors Do?

Aesthetic Powders The manufacturing and manufacture of aesthetic products create a good deal of dust that conveniently moves to all areas of the manufacturing facility navigate to this website and also makes the air dangerous. To control the issue, manufacturers set up dirt collection systems such as baghouse and cartridge kinds. Shot Blasting Dirt collection systems for shot blasting and sandblasting are required to gather the blowing up material, debris, and also dust.

The dirt collection system helps by removing blast product. Rock Dust Rock dirt collection systems are used at quarries and also mining procedures.

In the appropriate problems, accumulated dust can end up being hazardous, unsafe, and also dynamite. Any kind of build-up of dirt, in the presence of the ideal ignition resource, can create an explosion. In certain situations, dirt can self-ignite without requiring a firing up representative, such as when static develops up as the fragments rub together.

A preliminary understanding of the conditions that develop explosive dirt offers companies with the knowledge to stop such problems as well as be proactive in their reaction. Considering that surges can potentially harm workers, the Workplace for Security and Health And Wellness Management (OSHA) has developed a collection of requirements to lead companies in ensuring employee security.

Some Known Questions About Best Dust Extractors.

Other activities that can help in making a dust-filled atmosphere safe are: Explosion Vents Surge vents can be set up on a dirt collector system to provide different methods for fires or increasing gasses to get away. Explosion Locks Explosion locks operate under the exact same concept as click this link explosion vents.Preventative Upkeep Plan Of the different approaches to deal with potentially eruptive issues, proper treatment of the property and also keeping locations clean are the simplest and also most rational techniques for preventing explosive and flammable problems. Such strategies are typically established in sychronisation with safety and security employees as well as authorities that have jurisdiction.

They trap exhaust and lower the temperature level of warmed particles before they get in a dust-collecting gadget. They transport sparks and also embers away from the dust collection system, where the stimulates are cooled to avoid surges as well as fire.

Additionally, there are needs relating to the removal of combustible dust fragments. The primary emphasis of OSHA standards is a stipulation of the preventative measures being taken by a firm to safeguard the health and wellness of its staff members. Regardless of the absence of dirt collection requirements, OSHA does prefer that producers have a dirt collection system to manage dust accumulation.

The Main Principles Of Best Dust Extractors

Each industry has a different selection of contaminants as well as dangerous bits to be removed. With the growing issue for the atmosphere, dirt collection systems have come to be crucial to many industrial as well as manufacturing operations.Report this wiki page